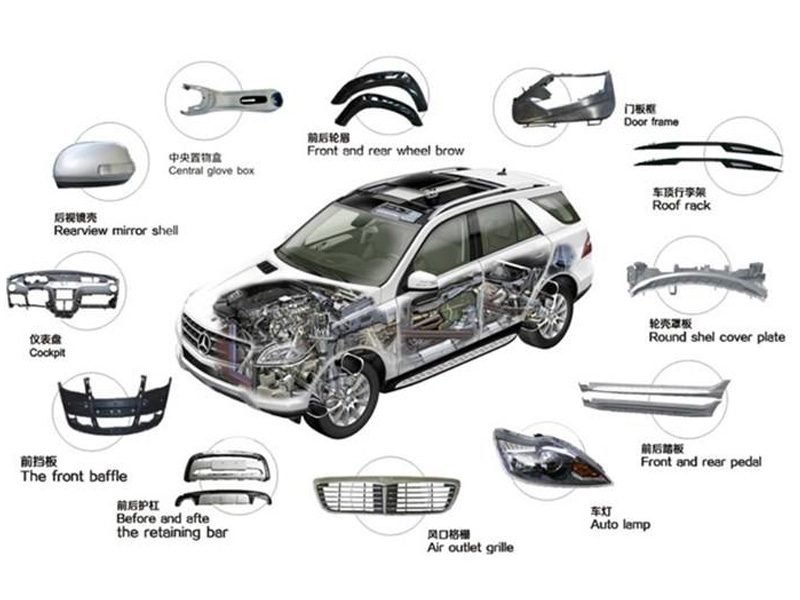

Precision Plastic mold & Die Parts Manufacturing

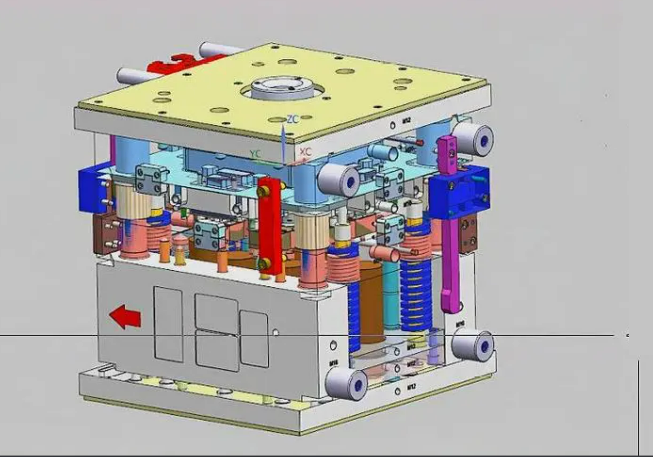

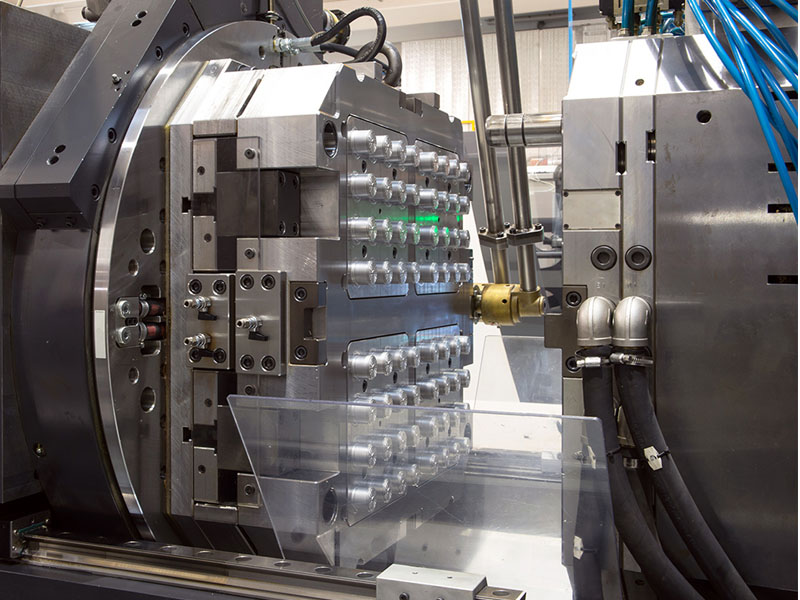

Since there are multiple solutions of plastic injection molds based on the different structure and shape products, there is almost no exactly the same mold, but the mold structure of the same product can have multiple solutions, and then tooling maker can choose the best plastic injection mold design solution. Therefor...